Enhancing Safety Protocols with Custom Solutions

Introduction:

A global leader in smart building solutions prioritizes safety, health, and sustainability across its operations. While utilizing Functional Devices’ Large Power Supply line, the company faced a challenge complying with safety regulations. Each time a panel was opened for maintenance, technicians had to wear cumbersome personal protective equipment (PPE) due to exposure to hazardous line voltage.

The Challenge:

Technicians faced challenges as they carried their electrical PPE bags into buildings, prepared to dress out, and potentially climb ladders to access large power supply units above the ceiling. The cumbersome PPE not only limited their peripheral vision, increasing the risk associated with ladder climbing but also added time to their tasks. Moreover, the heat generated by the PPE, particularly during the hot summer months, exacerbated discomfort and frustration.

Recognizing the urgent need for a solution, Functional Devices responded to the client’s request, understanding that this issue also impacts numerous other companies striving to maintain strict safety protocols for their personnel.

The Solution:

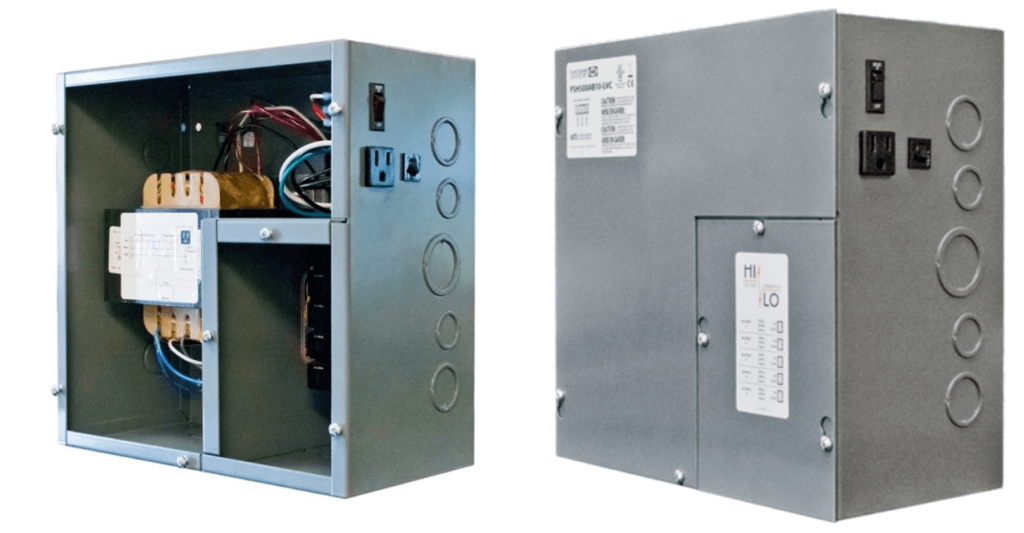

Functional Devices collaborated closely with the client to devise a practical solution. By introducing a low-voltage compartment and internal barrier within the enclosure, Functional Devices effectively separated hazardous line voltage from the low-voltage components, mitigating safety risks significantly. The innovative design allowed technicians to access low-voltage connections without exposing them to hazardous line voltage, enhancing both safety and efficiency.

The Process:

The client initially presented Functional Devices with a concept, demonstrating the need for a solution to their safety challenges. Functional Devices refined the concept by incorporating a divider inside the enclosure and modifying the cover to facilitate separate access to low-voltage components. This collaborative process resulted in a unique solution that exceeded expectations.

The Results:

The implementation of Functional Devices’ solution transformed safety protocols for the client, streamlining maintenance procedures, and reducing the time and resources spent on accessing switches and breakers. By prioritizing safety without compromising efficiency, the client realized significant cost savings and operational improvements.

Conclusion:

This partnership exemplifies Functional Devices’ commitment to engineering tailored solutions that address the unique challenges faced by our clients. If you’re seeking a trusted partner to enhance your engineering solutions, Functional Devices is here to assist. Contact us to explore opportunities to bring our ideas to life.

Are you facing challenges with your products or systems?

Let Functional Devices be your BAS OEM partner for custom solutions. Contact us today to explore how we can tailor our products to meet your unique requirements and drive success in your business.

Contact Us to Learn More

Ready to discuss your next BAS OEM project? We’re here to answer your questions and explore how our manufacturing capabilities can benefit your Building Automation Systems. Let’s build a partnership that drives success.